Properties

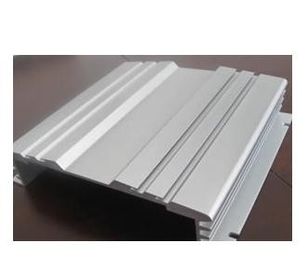

PE660 is an alkali corrosion resistance additive for aluminum anodizing.

It can significantly increase the critical concentration of aluminum ions to reduce the bottom sediment. It is suitable for mirror material and matt material.

1. Taking account of the use of alkali bath and aluminum extrusion traces, it is suitable for mirror material and matt material.

2. Great aluminum ion complexation performance,even if the concentration reached 140g / L ,

still without precipitation.

3. Using the surfactant, corrosion inhibitor,so it can make the aluminum work pieces surface delicate after leaving the alkali bath.

4. The bath is easy to control, with low consumption, and easy to maintain and manage.

5. To prevent too fast corrosion, resulting in pitting.

Bath composition and Operation condition

| Item | Range | Best condition |

| PE660 | 10 ~ 20g/L | 15g/L |

| Free alkali | 30~ 50g/L | 40-45g/L |

| Temperture | 30 ~ 60℃ | 40 ~ 50℃ |

| Time | 30s-10min | 60s-2min |

Note: If you use ultrasound, it is recommended to use the frequency of 40 ~ 60KHz ultrasonic, If the ultrasonic frequency too high,it may cause the work piece surface appearance problems.

Package

25 kg /1000kg