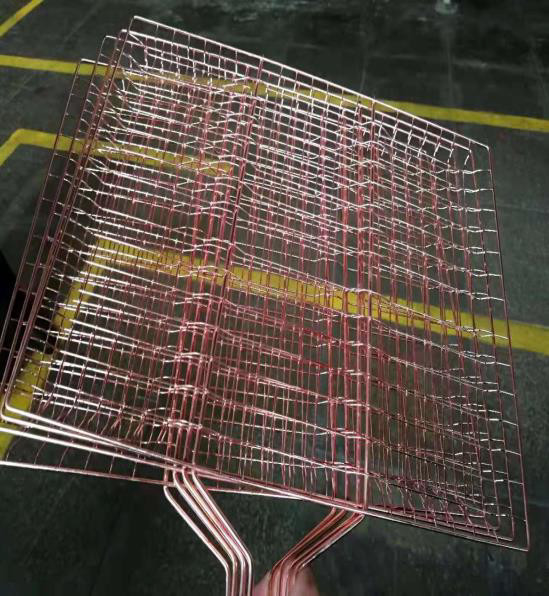

Direct Acid Copper Plating Process Steel Substrate Acid Copper Plating Solution Bright

-

Highlight

Direct Acid Copper Plating Process

,Steel Substrate Acid Copper Plating

,Direct Acid Copper Plating Brightener

-

TypeBrightener

-

CharacteristicAcid Copper Plating

-

FeatureDirect Copper Plating

-

SubstrateSteel And Stainless Steel

-

Place of OriginCHINA

-

Brand NameFENGFAN

-

Model NumberFI-ZL001

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsStandard export packaging

-

Delivery Time15-25 work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability200000pcs/day

Direct Acid Copper Plating Process Steel Substrate Acid Copper Plating Solution Bright

Direct Acid Copper Plating Process ; Steel Substrate Acid Copper Plating Solution Bright Copper Plating

Features

• It is cyanide free acid copper plating on steel and iron substrate, especially suitable for continuous plating.

• It can be the base layer, instead of semi-bright nickel or watt nickel or cyanide alkali copper plating.

• The copper plating layer thickness could be reached more than 200μm.

• It does not contain cyanide, so it is easy to treat the wastewater and has little pollution to the environment.

• The maintenance of the bath is simple and the service life is long.

• High speed copper plating, high current efficiency, and good deep plating ability, especially suitable for reel to reel large current high-speed copper plating.

BATH COMPOSITION AND OPERATION CONDITION

| Operation conditions | Range (rack plating) | Bath Make-up | ||

| Rendering copper | Thick copper | Bright copper | ||

| Copper sulphate(CuSO4·5H2O) | 80 ~ 250 g/L | 100 g/L | 100 g/L | 200 g/L |

| Sulfuric acid(H2SO4) | 60 ~ 100 g/L | 70 g/L | 80 g/L | 60 g/L |

| FI-ZL001 A | 5 ~ 25 ml/L | — | — | 3 ml/L |

| FI-ZL001 B | 50 ~ 100 ml/L | 50 ml/L | 100 ml/L | — |

| FI-ZL001 C | 50 ~ 100 ml/L | 50 ml/L | 100 ml/L | — |

| Temperature | 20 ~ 40 ℃ | 30 ℃ | 30 ℃ | 30 ℃ |

| Cathode current density | 1 ~ 10 A/dm2 | 1~3 A/dm2 | 3 A/dm2 | 3~10 A/dm2 |

| Filter | Continuous filtration | |||

| Agitation | Cathode movement or air agitation | |||

| Anode | Phosphor copper | |||

| Cathode | Anode and Cathode area ratio in 2:1 | |||