-

Highlight

EA15-90 Anionic Surfactant

,Zinc Plating Anionic Surfactant

,EA15-90 anionic solution

-

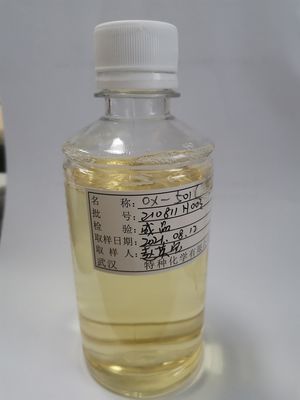

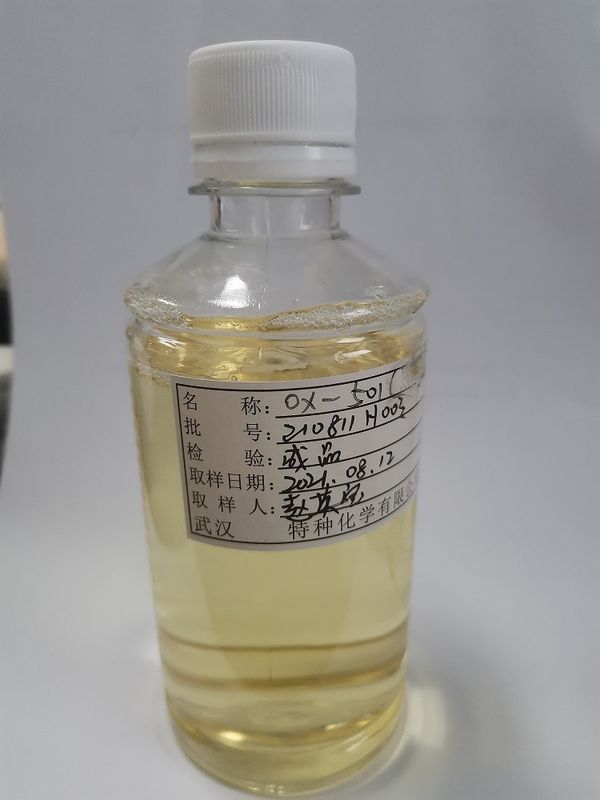

AppearanceLight Yellow To Yellowish Brown Transparent Viscous Liquid

-

PH5.0-9.0

-

Solid Content≥75%

-

Specific Gravity1.1g/cm3

-

Place of OriginCHINA

-

Brand NameFENGFAN

-

Model Number0X-501 ; 15-90

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsStandard export packaging

-

Delivery Time15-25 work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability200000pcs/day

EA15-90 Anionic Surfactant Carrier For Acid Zinc Plating

EA 15-90 ; Anionic surfactant ; Carrier for acid zinc plating

Product Description:

EA 15-90 is a fatty alcohol polyether sulfonic acid potassium salt, which belongs to anionic surfactant and carrier for acid zinc plating. Good salt resistance, bright coating can be formed in the region of medium and high current density, and has excellent hydrolysis resistance. It has good dispersion and emulsification in different concentrations of acid zinc plating solution, and has excellent comprehensive properties It can be used with non-ionic for better effect. Ox-501 is suitable for barrel plating and hanging plating.

Application:

EA 15-90 has good uniform and deep plating ability, can emulsify and disperse OCBA (o-chlorobenzaldehyde) and BAR (benzylidene), and has good compatibility with other additives.

1. Dosage of main brightener: 100-200g / L, which can be used with emulsifier or alone.

2. Dosage of softener: 200-250g / L, which can be combined with other negative and non carrier, with good comprehensive performance.

3. Applicable temperature range: 20-35 ℃.

4. Applicable pH value range: 5.5-6.5.

Packaging and storage:

25kg, 200kg and 1000kg plastic drums should be stored in cool, dry and ventilated warehouse and packaged in boxes.