W-710 Copper Nickel Chrome Layer Fast Stripper Electrolytic Stripping

-

Highlight

Chrome Layer Fast Stripper

,Electrolytic Stripping Chrome Layer Fast Stripper

,Nickel Layer Post Treatment Chemicals

-

FeaturesFasten Stripping Speed

-

TypeElectrolytic Stripping

-

Place of OriginCHINA

-

Brand NameFENG FAN

-

Model NumberW-710

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsStandard export packaging

-

Delivery Time15-25 work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability200000pcs/day

W-710 Copper Nickel Chrome Layer Fast Stripper Electrolytic Stripping

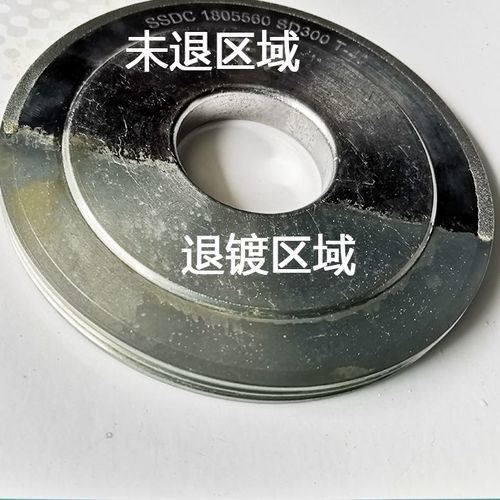

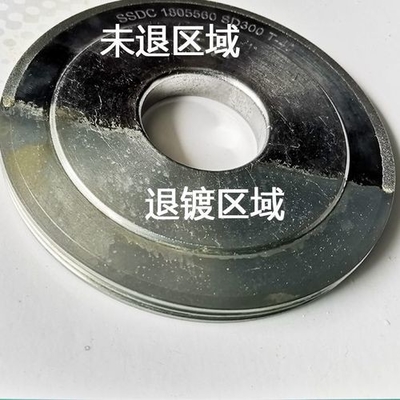

W-710 Copper/Nickel/Chrome Layer Fast Stripper ; Electrolytic Stripping

1. Features

1. W-710 layer is clean after stripping, to be able to replate directly.

2. W-710 bath solution can be used for a long time.

3. W-710 process is stable as well as easy operation and fast stripping.

4. W-710 can fasten stripping speed.

2. Process specification conditions

| Item | Index |

| W-710 Stripper | 200-250 g/L |

| DA | 5-10A/dm2 |

| PH | 7-10.5 |

| Temperature | Room temperature |

| SK:SA | > 3:1 |

| Cathode Material | Iron Plate |

3. Application

1. Dissolve stripper into stripping bath according to formula, agitate, add water to requested volume after well dissolved, then you can use it.

2. Use iron bath as stripping bath, and use iron bath as cathode to ensure cathode square measure big enough. In order to avoid dross interfered, the stripping bath should be deep.

3. Plating rack beneath the water should be made of steel, do not use copper material.

4. Take workpiece out immediately to prevent its luster from damaging after layer stripping. If stripped workpiece can not be plated at once, it should be immersed into 5% NaOH solution.

5. It is not important to move anode or not, but do not agitate with air.

6. Filter and get rid of sediments regularly. It is not appropriate to replenish stripper into bath directly. Stripper should be well dissolved in another vessel.

4. Solution Maintenance and Management

1. When pH value is raising, use HNO3 to adjust.

2. The following factors are able to affect stripping speed, it should be adjusted appropriately.

| Problem | Solution |

| Assay of stripper and additive is a little low | Replenish stripper and additive |

| Turbid solution | Filter by placing it or siphon |

| Temperature of bath exceeds 60℃ | Cool down appropriately |

| Density of currency is a little low | Raise |

Declaration: All about this product suggestions are based on our trust test and data, for reference only.