-

TypeBright Tin Plating

-

UseTin Plating

-

ItemChemical Auxiliary Agent

-

FeatureHigh Speed Plating

-

Place of OriginCHINA

-

Brand NameFENGFAN

-

Model NumberSn-839

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsStandard export packaging

-

Delivery Time15-25 work days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

-

Supply Ability200000pcs/day

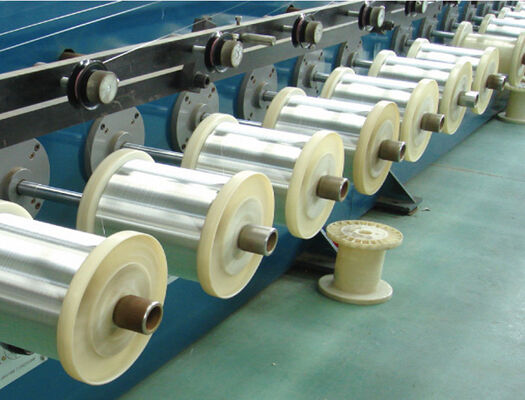

Sn-839 continuous bright tin plating process

The Sn-839 process is suitable for continuous bright tin plating processes at high speed. It is designed for strip, wire, connectors, lead frames, etc. The main features and advantages of the process are briefly described below.

1, The plating is not easy to produce pinholes and fogging, and can get uniform bright plating in a wide range of current.

2, Lead-free and cadmium-free, complying with ROHS and ELV regulations.

3, Very low organic content, minimal discolouration after steam and heat treatment, excellent solderability.

4, High current efficiency, stable plating solution, easy to control.

5, The plating retains its good ductility and weldability even after storage.

Solution composition

Optimal Range

Sn2+ 50.0 g/L 50-80 g/L

Methanesulfonic acid 200 g/L 150-220 g/L

Sn-839A carrier 20ml/l 15-25 ml/l

Sn-839B brightener 5ml/l 3- 10 ml/l

Temp. 18-25℃ 18-25℃

Cathode current density 20A/dm2 5-40A/dm2

Anode:Cathode area 2 :1 2 :1

Voltage 1-3V 1-3V

Deposition rate Minimum 10 microns per minute at a current density of 20A/dm2