Sn-827 High Speed Matte Tin Plating Process with Methyl Sulfonic Acid for Excellent Solderability

-

Highlight

High Speed Plating Matte Tin

,Methyl Sulfonic Acid Tin Plating

,Excellent Solderability Electroplating Chemical

-

TypeMatte Tin Plating

-

UseTin Plating

-

ItemChemical Auxiliary Agent

-

FeatureHigh Speed Plating

-

Place of OriginCHINA

-

Brand NameFENGFAN

-

Model NumberSn-839

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsStandard export packaging

-

Delivery Time15-25 work days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

-

Supply Ability200000pcs/day

Sn-827 High Speed Matte Tin Plating Process with Methyl Sulfonic Acid for Excellent Solderability

Sn-827 High-Speed Matte Tin Plating Process

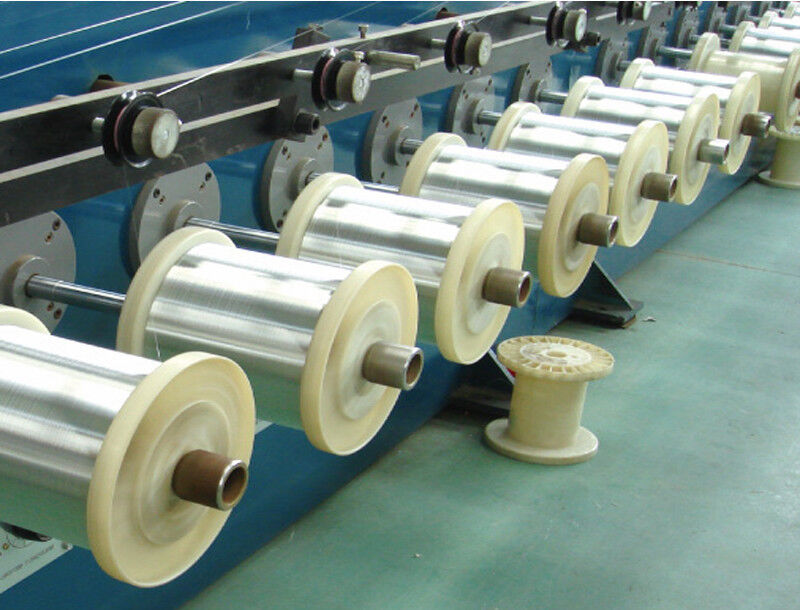

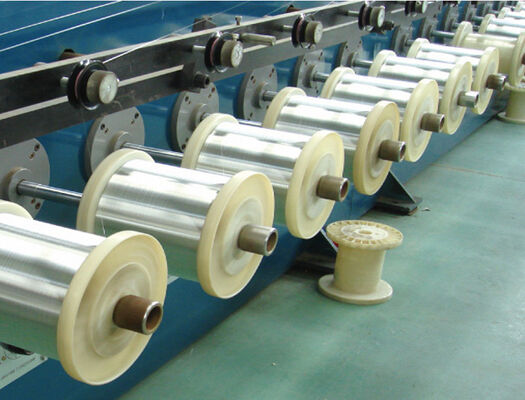

Sn-827 is a methyl sulfonic acid-based tin plating process engineered for high-speed electroplating applications. This advanced formulation produces a dark-silver matte coating with exceptional performance characteristics.

Key Features

- Designed for high-speed electroplating operations

- Operates effectively at high current densities

- Low-foaming formulation for stable performance

- Produces smooth plating with excellent solderability

- Non-corrosive to titanium, ceramics, and glass components

- Formaldehyde-free and acetaldehyde-free composition

- Non-flammable substance for enhanced safety

Solution Composition & Operating Parameters

| Parameter | Optimal Value | Operating Range |

|---|---|---|

| Sn2+ | 60.0 g/L | 40-90 g/L |

| Methanesulfonic Acid | 100 g/L | 80-200 g/L |

| Sn-827 Additive | 40 ml/L | 40 ml/L |

| Temperature | 20-25℃ | 20-25℃ |

| Cathode Current Density | 10-50 A/dm² | 10-50 A/dm² |

Process Specifications

Plating Solution Flow Direction: Opposite to the direction of workpiece movement

Deposition Rate: Minimum 7.5 microns per minute at 15 A/dm² current density

Deposition Rate: Minimum 7.5 microns per minute at 15 A/dm² current density

Important Note: Sn-827 high-speed matte tin plating additive should not be stored for extended periods at temperatures above 30℃.