Electroplating process of matte tin-lead alloy ; FI-T210 ; PCB electroplating additive

-

Highlight

surfactant chemistry

,surface active agents

-

TypeTin Lead Alloy

-

UsePCB, IC And Other Electronic Components

-

ModelElectroplating Additive

-

CharacteristicMatte

-

Place of OriginChina

-

Brand NameFENGFAN

-

Model NumberFI-T210

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsStandard export packaging

-

Delivery Time15-25 work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability200000pcs/day

Electroplating process of matte tin-lead alloy ; FI-T210 ; PCB electroplating additive

Electroplating process of matte tin lead alloy FI-T210

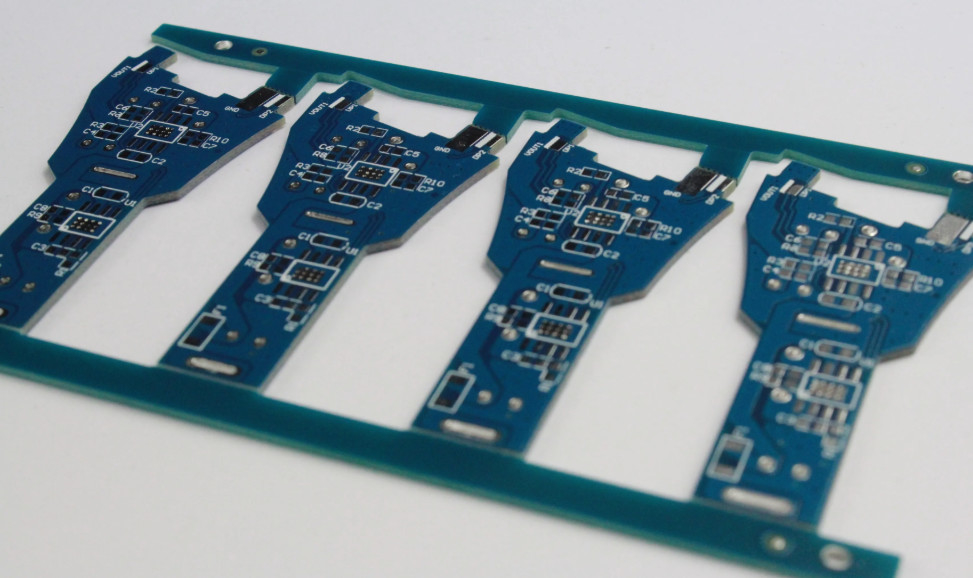

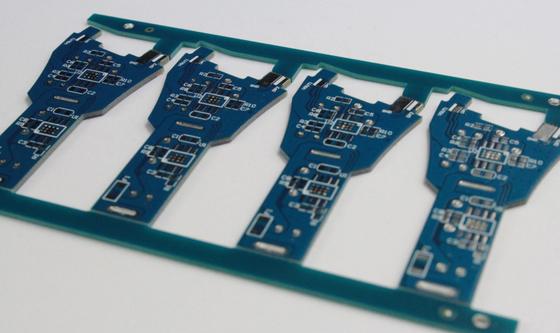

FI-T210 series matte tin lead alloy plating process is a new type of fluorine free boric acid and low foam tin lead alloy plating system, which is suitable for electroplating equipment such as rack plating and barrel plating. Fine and uniform non bright Sn Pb alloy coating can be plated in a wide range of current density; The process is also suitable for electroplating tin lead alloy on PCB, IC and other electronic components.

1. Properties

1) The organic acid system tin lead alloy process has no fluoroboric acid, low corrosivity and easy wastewater treatment;

2) Single additive, easy to operate, stable plating solution and convenient maintenance;

3) It has highly stable Sn Pb alloy proportion and uniform coating thickness distribution in a wide range of current density;

4) Fine and uniform coating appearance;

5) high efficiency and little foam;

6) Superior welding performance.

2. Bath composition and Operation condition

1) Bath composition:

| Organic acid | 100-200ml/L |

| Organotin | 43.3-76.7ml/L |

| Organic lead | 2.2-6.6ml/L |

| FI-T210M | 25-35ml/L |

2) Drug composition:

| Formula and Operation Condition | Range | Optimum |

| Acid concentration | 100-200ml/L | 150ml |

| Tin metal | 13-23g/L | 18g/L |

| Lead metal | 1-3g/L | 2g/L |