FF-7705 Methylsulfonic Acid Bright Tin Plating Process with Fast Deposition Stable Process and Excellent Welding Performance

-

Highlight

Fast Deposition Bright Tin Plating Process

,Stable Process Methylsulfonic Acid Plating

,Excellent Welding Performance Electroplating Chemical

-

TypeBrightener

-

UseTin Plating

-

ItemChemical Auxiliary Agent

-

FeatureFast Deposition, Stable Process

-

Place of OriginCHINA

-

Brand NameFENGFAN

-

Model NumberFF-7705

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsStandard export packaging

-

Delivery Time15-25 work days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

-

Supply Ability200000pcs/day

FF-7705 Methylsulfonic Acid Bright Tin Plating Process with Fast Deposition Stable Process and Excellent Welding Performance

FF-7705 Methylsulfonic Acid Bright Tin Plating Process

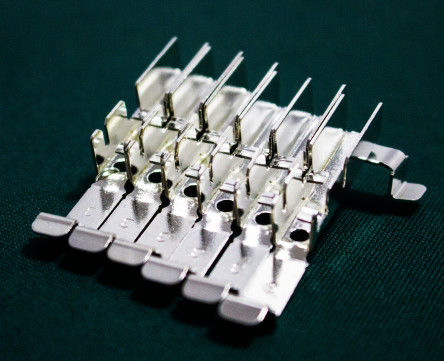

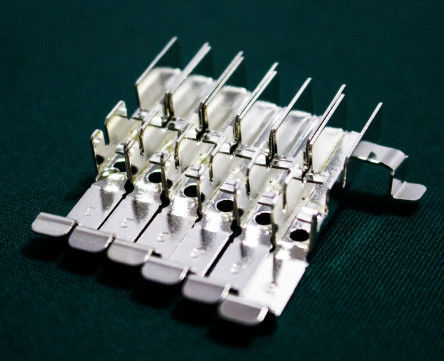

The FF-7705 process offers excellent walking ability, superior welding performance for coatings, and produces a uniformly bright white finish. This high-stability solution is easy to maintain and suitable for both rack plating and barrel tin plating processes.

Key Features

- Excellent walking ability

- Superior welding performance of coatings

- Bright white finish with uniform appearance

- High stability and easy maintenance

- Suitable for rack plating and barrel tin plating processes

Applicable Equipment and Materials

- Equipment: Polyethylene, polypropylene, PVC

- Agitation: Rack plating with cathode movement (3-4 m/min); aeration agitation not applicable

- Anodes: Must use pure tin anodes (impure anodes adversely affect coating); PP anode bags required for anode baskets

- Circulation/Filtration: Requires system operating at 4-5 cycles per hour with filter mesh size less than 5-10 µm

- Rectifier: Must use rectifier with residual ripple below 5%

Process Specification Conditions

| Parameter | Value |

|---|---|

| (CH3SO3)2Sn | 45-60 ml/L |

| CH3SO3H | 100-180 ml/L |

| FF-7705A | 40-50 ml/L |

| FF-7705B | 8-12 ml/L |

| Temperature | Room temperature |

| Current density | 0.5-3.0 A/dm2 |

| Filtering | Continuous |

| Cathode movement | Required |